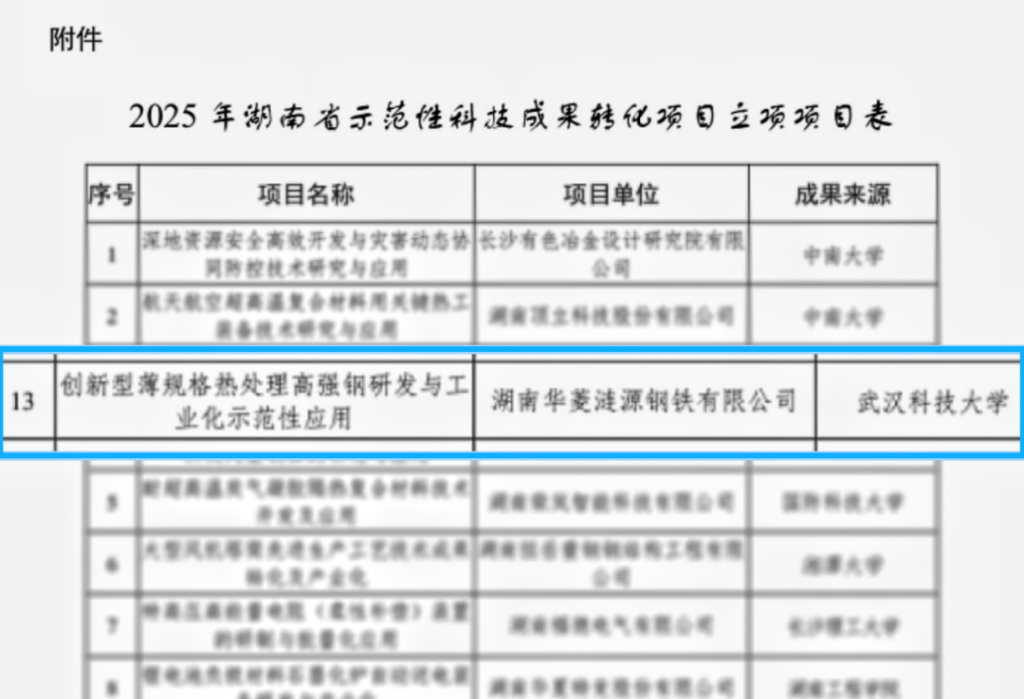

Recently, the Hunan Provincial Department of Science and Technology approved 15 provincial-level demonstration scientific and technological achievements transformation projects for 2025. After application recommendation, formal review and other procedures, it was decided to approve Liangang’s “Innovative Thin-Gauge Heat-Treated High-Strength Steel Research and Development and Industrial Demonstration Application” and other 2025 Hunan Demonstration Scientific and Technological Achievements Transformation Projects.

Today, Liangang’s heat-treated high-strength steel has become a typical product among my country’s high-end special steels that breaks the foreign technology blockade. It has also injected strong momentum into the raw material security of my country’s engineering machinery industry chain and has become an important engine for promoting the green and low-carbon development of the manufacturing industry.

From “stuck neck” to “strong support”

For a long time, the market for high-end steel used in my country’s construction machinery has been monopolized by international giants, creating a bottleneck that has hindered the development of the industry. At the same time, driven by the “dual carbon” strategy, lightweighting construction machinery has become an industry consensus. Targeted at this industry need, Liangang, after more than a decade of dedicated research and development, has achieved independent production of a series of high-quality, GPa-grade, ultra-high-strength, thin-gauge, heat-treated high-strength steel plates, providing core material support for the green transformation of the industrial chain.

Relying on the national enterprise technology center and Asia’s largest medium and thin-gauge heat treatment base, Liangang insists on the close connection of “production-sales-research” and efficiently opens up the “last mile” of industrial application.

The project focused on industry pain points, overcoming the technical barriers of microstructure control and low internal stress control in high-strength steel plates. The project developed high-strength structural steel plates with yield strengths ranging from 600 to 1400 MPa and a series of high-strength, toughness, and wear-resistant steels with hardnesses ranging from 400 to 650 HBW. This resulted in a comprehensive product range of over 40 grades and a comprehensive processing and application technology system for related steel grades. These products are widely used in industries such as construction machinery, mining trucks, dump trucks, coal mining machinery, and port machinery, significantly enhancing the competitiveness of downstream customers’ products and significantly promoting the lightweighting and low-carbon development of trillion-yuan-level industrial clusters such as construction machinery and new energy equipment.