As the nation’s requirements for infrastructure construction quality continue to escalate, particularly amid Hunan Province’s recent crackdown on industry irregularities such as “slimming rebar,” Liangang’s “Shuangling” brand hot-rolled ribbed rebar, with its exceptional craftsmanship and unwavering strength, has become the “steel backbone” safeguarding the quality of key national projects. From nuclear power plant “restricted zones” to superbridges spanning natural chasms, Liangang, through high-quality orders and rigorous certifications, embodies the quality standards of Made in China and the responsibility of a state-owned enterprise.

Tackle the “forbidden zone” of nuclear power and establish a monument to industry quality

The nuclear power sector represents the highest threshold for steel quality. In 2020, Liangang achieved a major breakthrough – its “Shuangling” brand hot-rolled ribbed steel bars were successfully used in the second phase of the Hainan Changjiang Nuclear Power Plant, entering the core field of nuclear power construction in one fell swoop. This not only means that the product has passed the extremely stringent HAF003 nuclear safety standard certification, but also marks Liangang as one of the few leading companies in China that can supply steel bars for key parts of the nuclear island. To ensure absolute safety, Liangang has tailored 27 special quality control procedures to meet the special needs of nuclear power steel bars (such as corrosion resistance, high weldability, and extreme seismic resistance), achieving refined tracking of the entire process from steelmaking to rolling. This ultimate pursuit of quality has laid a solid foundation for the subsequent acceptance of nuclear power plant projects such as Zhejiang Sanmen and Jinqimen, and established its absolute leading position in the nuclear power field.

Connecting the arteries of a great nation and turning natural barriers into thoroughfares

Liangang steel also plays a key role in the nation’s extensive transportation network. “Shuangling” brand hot-rolled ribbed steel bars, characterized by high strength, excellent durability, and strong seismic resistance, meet the demands of modern construction, which is moving towards taller buildings, larger spans, and heavier loads. The high-performance, extreme-size (36-50mm) HRB500E steel bar boasts a strength of up to 600 MPa, far exceeding that of ordinary hot-rolled ribbed steel bars. This steel was used in the construction of key columns and piers for the Guinness World Record-breaking Guanyin Temple Yangtze River Bridge and the Libu Highway-Rail Yangtze River Bridge, providing a solid foundation for the stability and safety of these mega-projects.

Technology drives innovation and sets a benchmark for China’s manufacturing

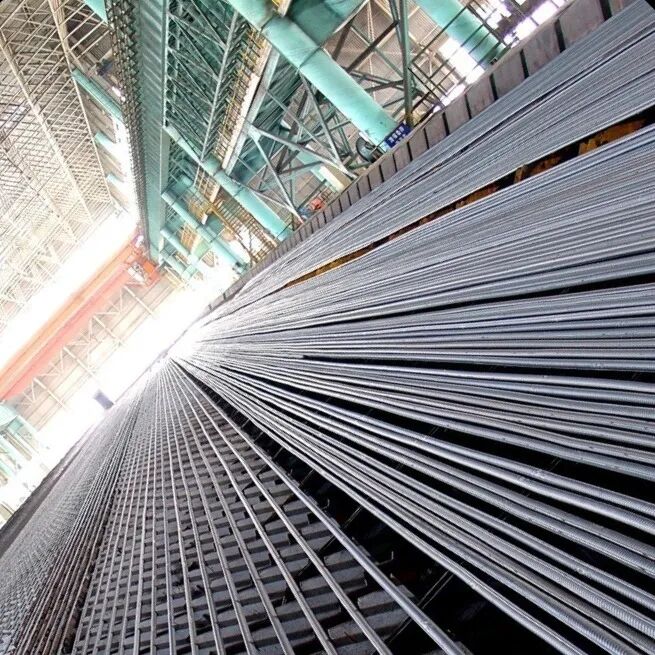

Excellent quality comes from continuous technological innovation and manufacturing strength. Liangang has the fastest rolling speed bar production line in China (up to 45 meters per second), and the product size tolerance can be precisely controlled within ±0.1 mm, ensuring the quality of each steel bar. Relying on advanced clean steel smelting technology, product quality is continuously improved, and ribbed steel bars are constantly developing towards high strength and corrosion resistance. Taking the current highest grade and highest strength HRB600 hot-rolled ribbed steel bars as an example, Liangang has broken through the technical bottleneck of large-scale production through technical research, and jointly with Changsha Rail, Hunan University, China Construction Fifth Bureau and other units to compile the province’s “Technical Standards for Hot-Rolled Ribbed HRB600 Grade Reinforced Concrete Structures”, which will be first used in batches in the Changsha Metro Project in 2022.