On Tuesday, Ly Steel dispatched a dedicated quality assurance team to Nanjing to conduct a critical pre-shipment inspection of a batch of abrasion-resistant and high-strength steel plates destined for key projects. This routine yet vital procedure underscores the company’s unwavering commitment to delivering products that meet the highest standards of quality and precision.

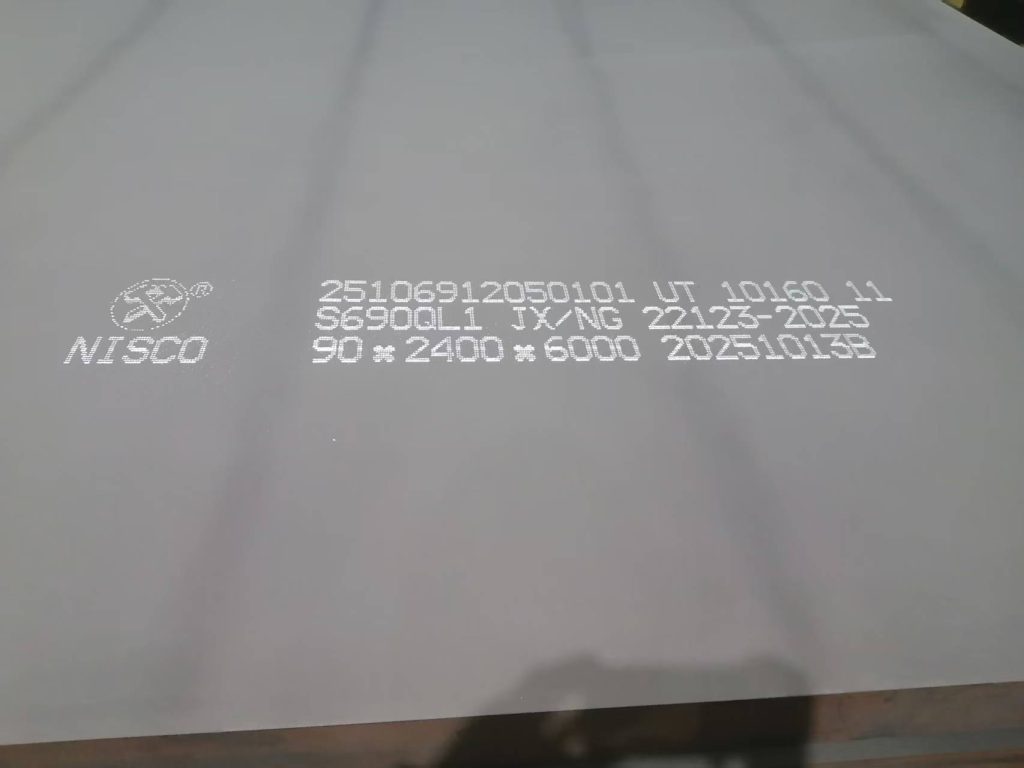

The inspection focused on two advanced steel grades: the NiRes ET abrasion-resistant steel and the S690QL 1 high-strength steel. The on-site audit was comprehensive, covering several key parameters to ensure contractual and specification compliance. The team meticulously examined the surface condition of each plate for any signs of damage or imperfections that could impact performance. Furthermore, each plate’s identification tags were verified for accuracy and traceability. The physical dimensions—including length, width, and thickness—were precisely measured against the required tolerances. The inspection also included a full quantity check for each grade to confirm the order completeness.

“This inspection protocol is an integral part of our supply chain management,” stated the Quality Manager at Ly Steel. “By verifying the quality and specifications of materials like NiRes ET and S690QL 1 at the source, we proactively mitigate risks for our clients and ensure the seamless integration of these components into their final applications, whether in heavy machinery, mining equipment, or critical structural frameworks.”

The successful completion of this inspection in Nanjing marks another step in Ly Steel’s ongoing mission to provide certified, reliable, and high-performance steel products to the global market.