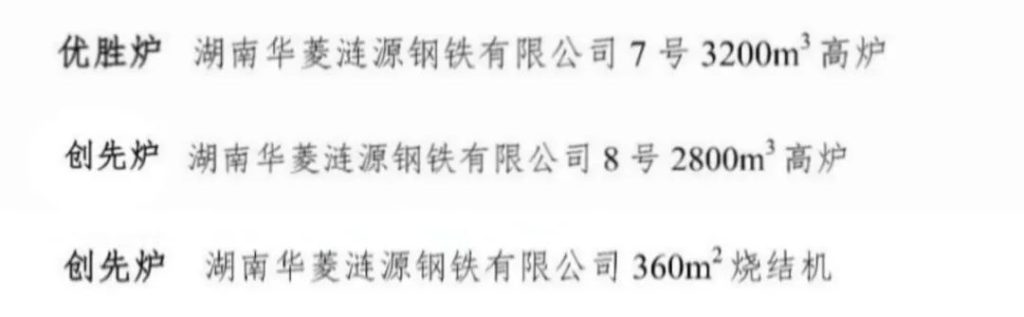

Recently, the results of the 2024 “National Benchmarking Competition for Energy Saving and Consumption Reduction in Key Large-Scale Steel Production Equipment” were announced. The competition was jointly organized by the China National Committee of the Chinese Mechanical, Metallurgical, and Building Materials Workers’ Union and the China Iron and Steel Association.

In terms of the blast furnace system, Liansteel has achieved stable high-wind-temperature, low-consumption operation by intelligently optimizing the air-fuel ratio in hot blast stoves through dynamic adjustments. Additionally, the company has enhanced the stability of raw material and fuel quality, optimized the coordination between upper and lower furnace operational parameters, and leveraged intelligent systems for furnace condition analysis, enabling long-term high-output, low-consumption operation of its blast furnaces.

In the sintering system, Liansteel has implemented steam recovery for material layer injection and infrared imaging of the machine-end cross-section, enhancing self-heat accumulation in the sinter bed and precise control of fuel blending ratios. These measures have effectively reduced solid fuel consumption by 1.2 kg/t while improving process stability.

Additionally, optimized flue interconnection balanced gas flow distribution, reduced the vertical sintering speed differential between both sides, and cut the return fines rate by approximately 0.6%. Concurrently, the main exhaust fan current was reduced by 10A, achieving both quality improvement and energy savings.

The 360m² sintering machine has demonstrated year-on-year gains in output and product quality, with multiple technical and economic indicators consistently ranking among the industry’s best.