In the world of industrial materials, where durability dictates efficiency and cost, the choice between premium wear-resistant steels is critical. Today, we spotlight a key comparison in this domain: Wear-resistant Steel VS MN13, two titans serving in high-impact, high-abrasion environments. Their distinct mechanical profiles make them suitable for vastly different battlefield conditions.

MN13, is celebrated for its legendary work-hardening capability. Under relentless impact and pressure, its surface hardness can increase dramatically from an initial 200 HB to over 550 HB, forming an ultra-hard layer while retaining a tough, shock-absorbing core. This unique property makes it the undisputed champion for applications like railway frogs, crusher jaws, and excavator buckets in mining, where severe pounding is the primary mode of wear. Its high manganese content (11-14%) is the secret behind this transformative ability.

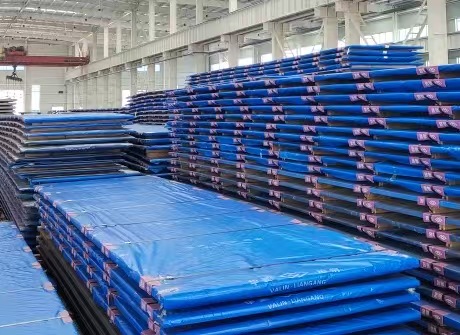

In contrast, standard wear-resistant steel plates take a different approach. They achieve their high surface hardness—often ranging from 360 to 500 HB or more directly from the mill—through advanced heat treatment and alloying with elements like chromium, boron, and molybdenum. This provides exceptional, consistent resistance to sliding abrasion and scratching. However, their toughness is generally lower than that of MN13, making them less ideal for extreme, repetitive impact. They excel in applications like dump truck liners, conveyor chutes, and mining shovel buckets, where constant scraping and grinding are the main challenges.

The core of the Wear-resistant Steel VS MN13 debate, therefore, hinges not on which is universally “better,” but on the specific nature of the assault they must endure. The choice is a strategic one: for extreme, high-energy impact that would shatter harder but more brittle materials, the adaptive, self-hardening nature of MN13 is often irreplaceable. For environments dominated by relentless, low-impact abrasion where maximum initial hardness is key, a traditional wear-resistant steel plate offers superior and more economical longevity.

In conclusion, the mechanical face-off between these two material classes provides a perfect lesson in application-specific engineering. Understanding their fundamental differences—MN13’s dynamic hardening versus the static, high hardness of wear-resistant plate—is the first step to unlocking greater equipment lifespan, safety, and productivity in the world’s most demanding industries.