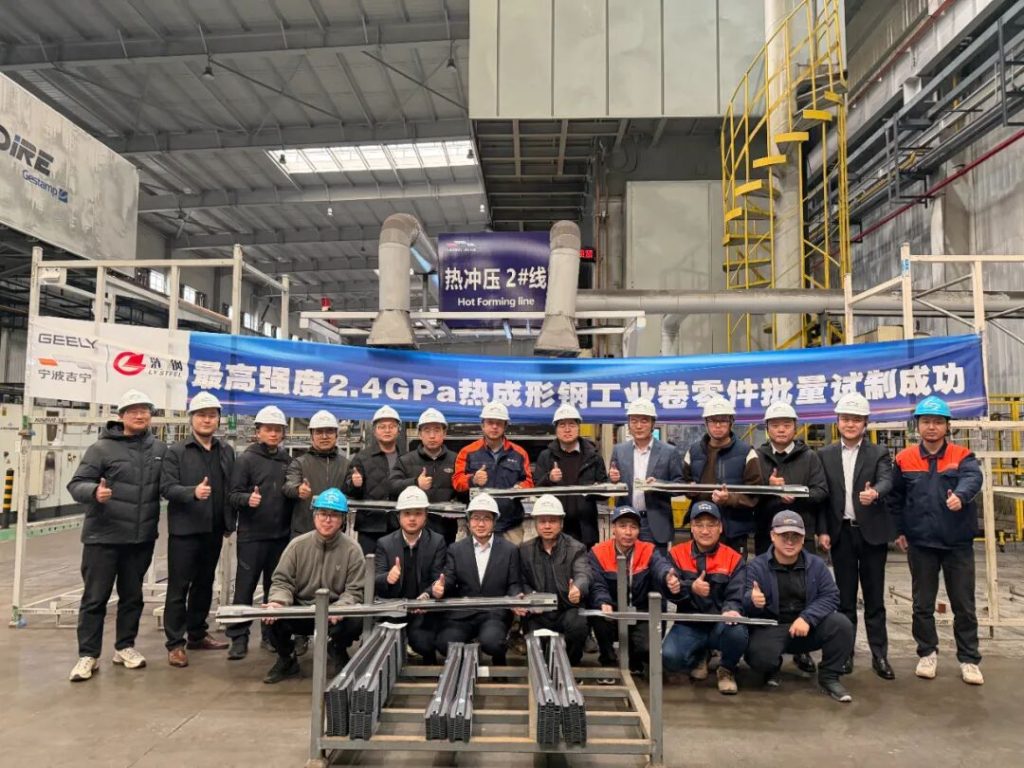

A major leap forward in vehicle safety has been achieved. Liangang Steel and Geely Auto have successfully completed trial production of the world’s strongest 2.4GPa hot-formed steel, marking a new era in automotive material strength and passenger protection.

Dubbed the “skeleton of automotive safety,” hot-formed steel is crucial for protecting passengers during collisions. The new material, developed for door anti-collision beams, surpasses previous industry limits by over 20% in strength while maintaining excellent formability and toughness.

This milestone establishes Liangang as China’s first steelmaker capable of mass-producing this ultra-high-strength material in coil form. The achievement resulted from close collaboration between Liangang’s advanced materials expertise and Geely’s automotive engineering leadership.

The breakthrough supports the automotive industry’s ongoing shift toward safer, lighter, and more environmentally friendly vehicles. As global safety standards become increasingly stringent, innovations like 2.4GPa hot-formed steel will play a vital role in designing next-generation vehicles that offer enhanced protection without compromising efficiency.

Both companies plan to expand application of this material to more critical safety components, contributing to higher safety ratings and advancing China’s role in global automotive innovation.